precise Spice

The Precise Spice is a fully mechanical spice container with a built in measuring and dispensing system.

Market analysis shows that measuring spoons are rarely used as often as intended. From an anthropological study shadowing 3 people cooking in their kitchens, none of the participants used a measuring spoon despite owning 40 spice containers on average. In addition, a user survey with 20 responses indicated that people avoid using measuring spoons to avoid additional dishwashing.

Our research identified only one company (KitchenArt) currently mass-producing an automatic spice measuring device. Their standard model consists of containers with a ratchet and pawl that spins a ¼ teaspoon partitioner with the turn of a dial. When not in use, containers are stored on a carousel that is free to spin.

A combination of product reviews and user studies indicates that this competitor product is unintuitive; consumers were confused by the measuring mechanism and frustrated by the amount of effort required to dispense larger amounts (e.g., 1 tablespoon). Consumers were also skeptical of the accuracy of the measuring system.

Based on these findings, we assert that there is a potential market for a spice measuring device towards young, affluent home cooks. Such a solution would therefore have the following qualities:

Intuitive to use

Easy to store

Provides measurements within 5% variance

Can dispense in increments of ¼ teaspoon, up to 1 tablespoon

Dispenses larger amounts as quickly as small amounts

Aesthetically pleasing

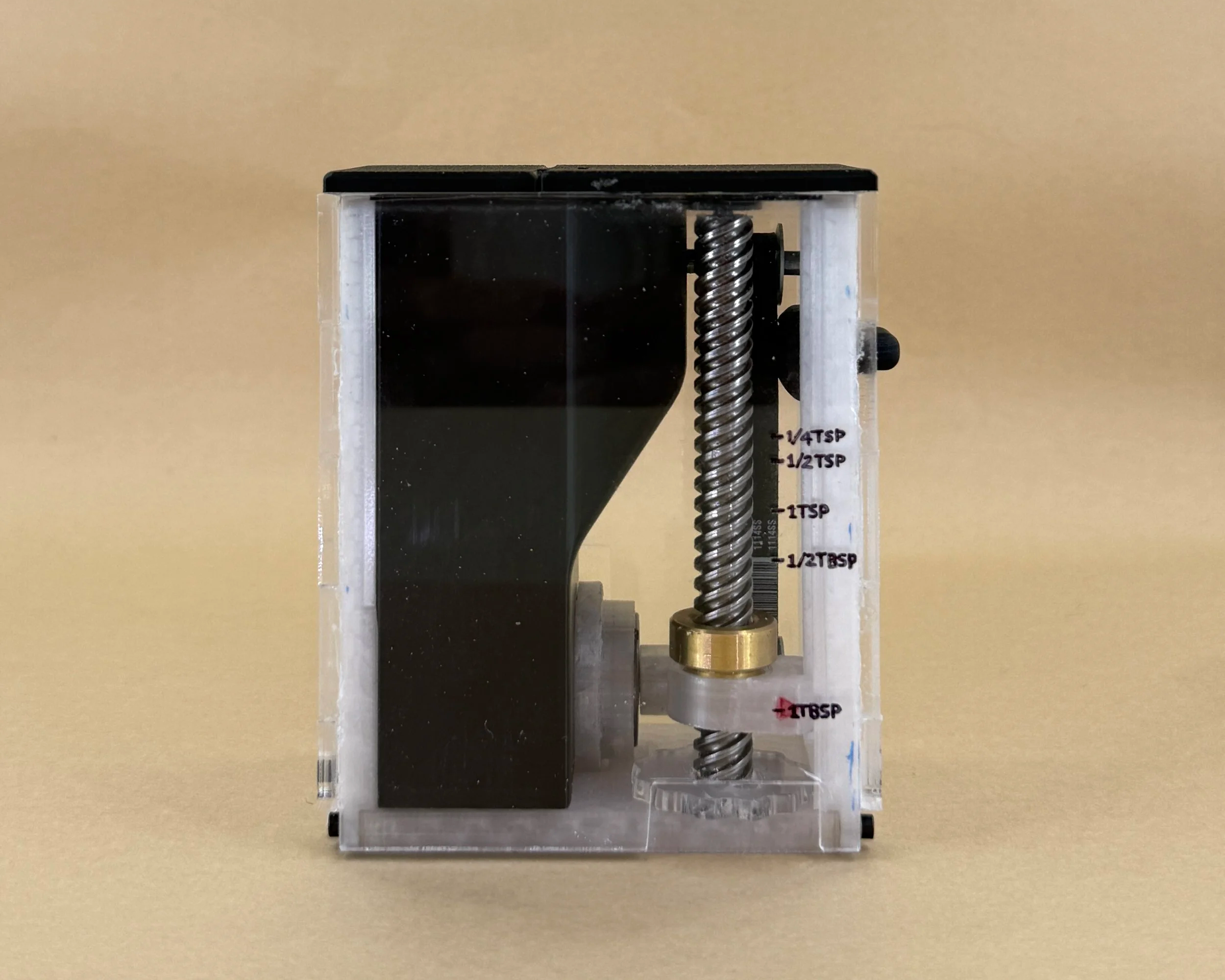

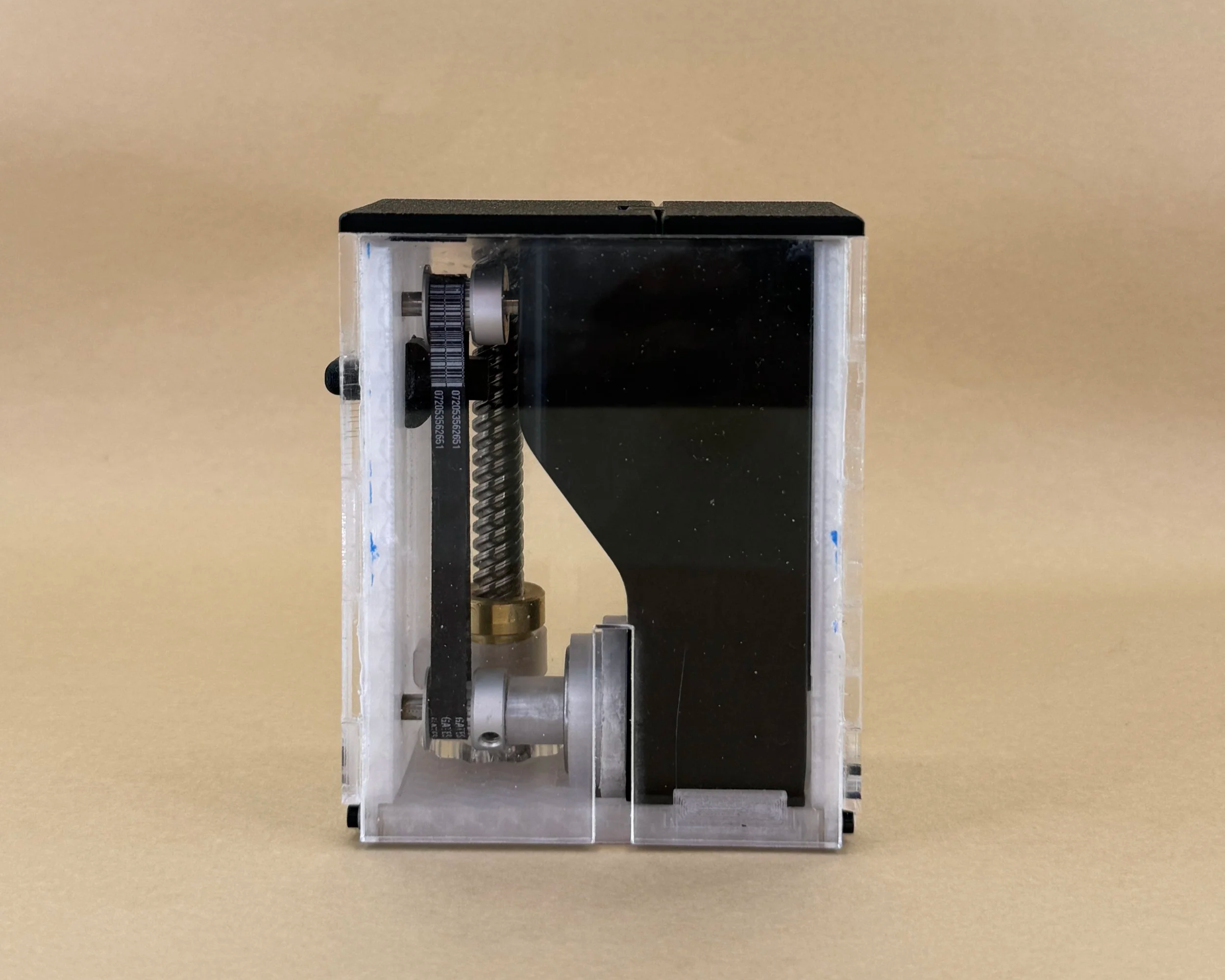

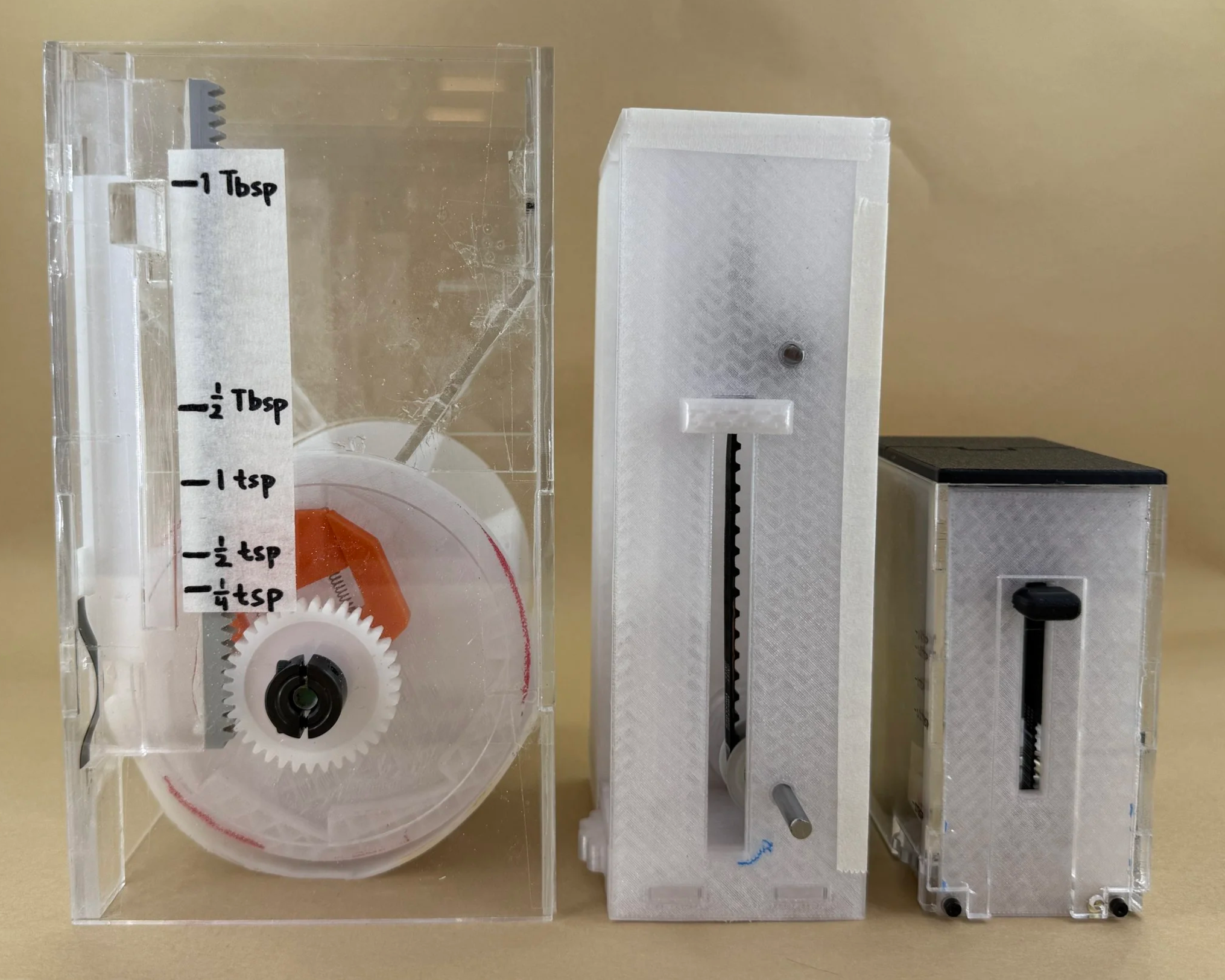

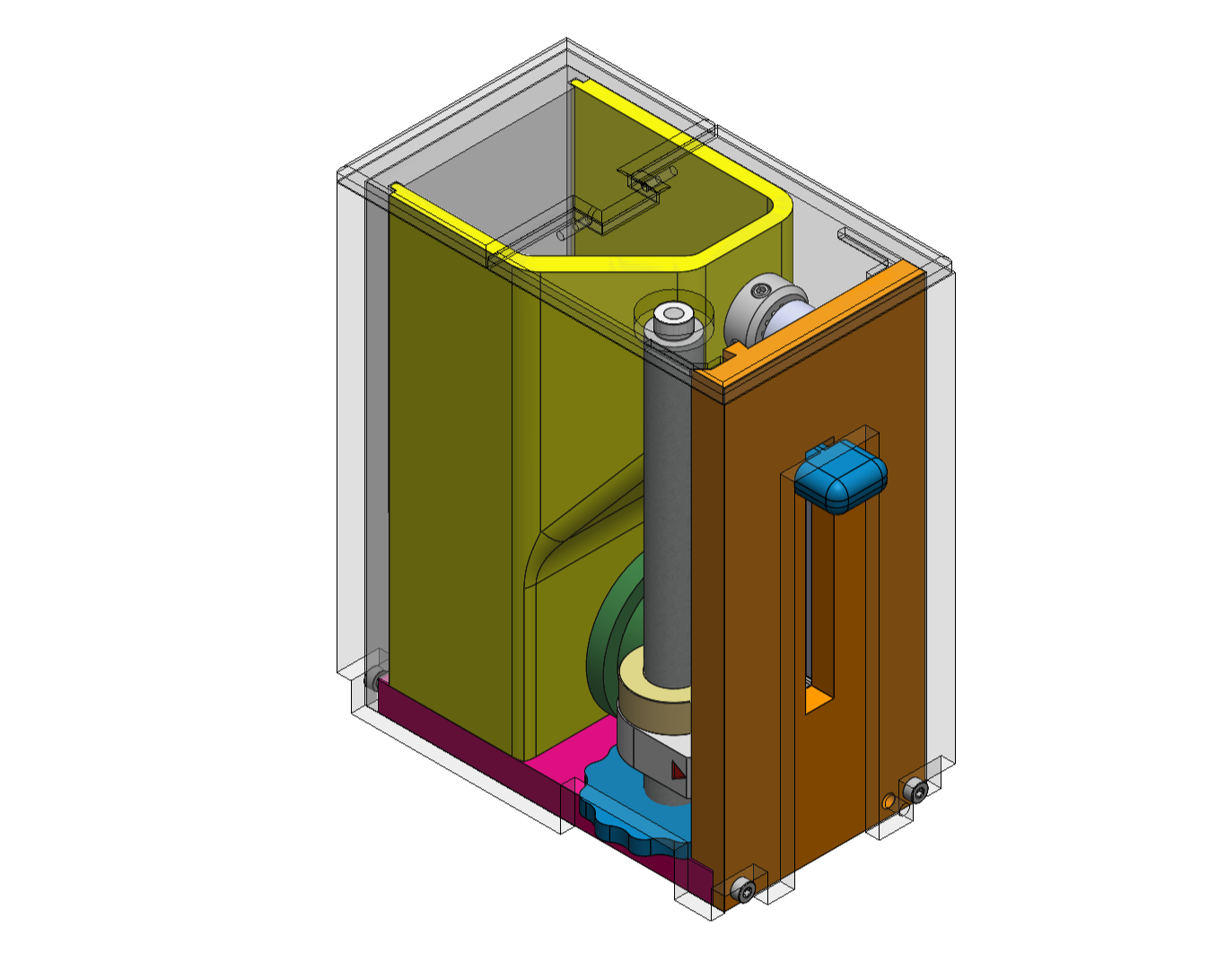

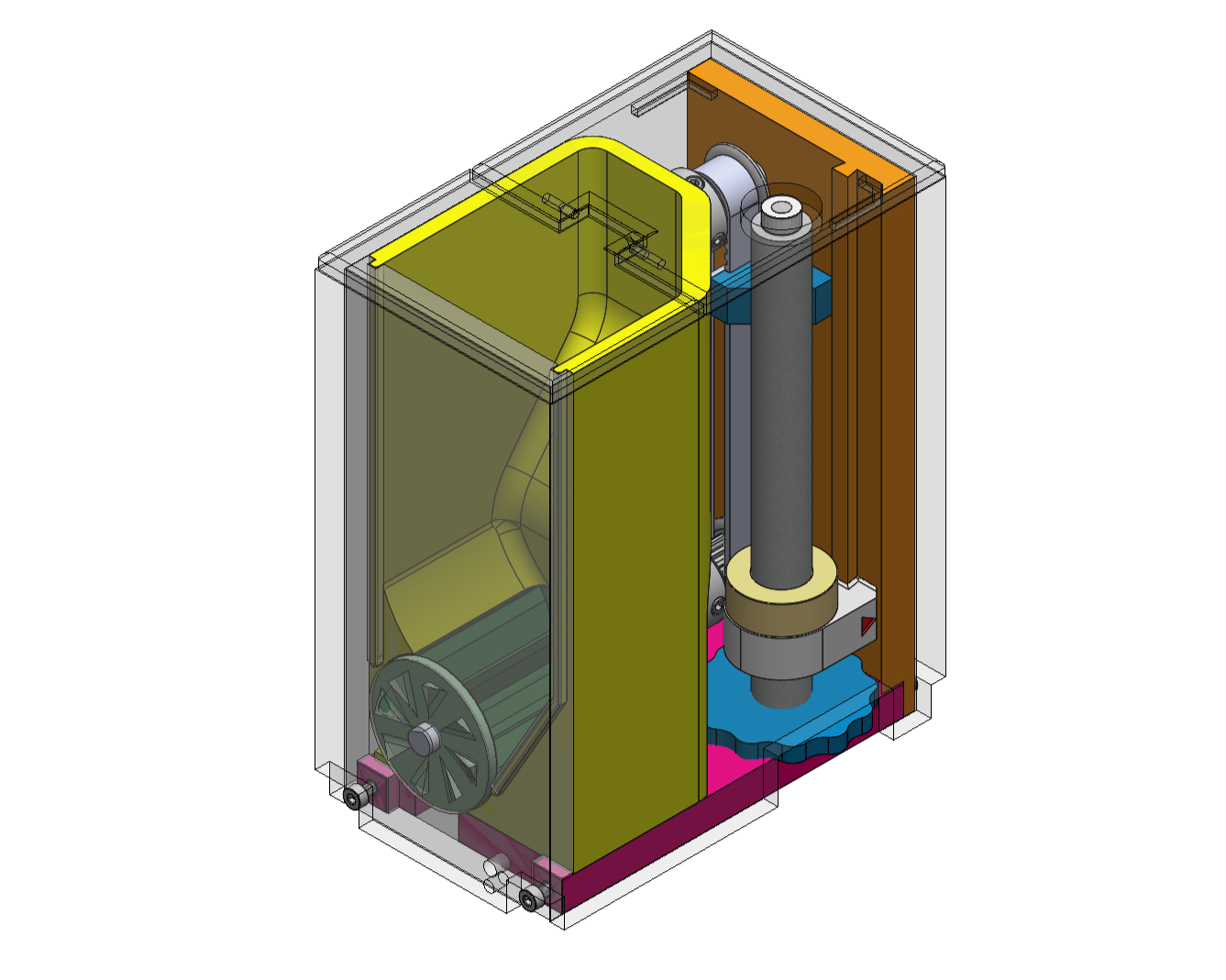

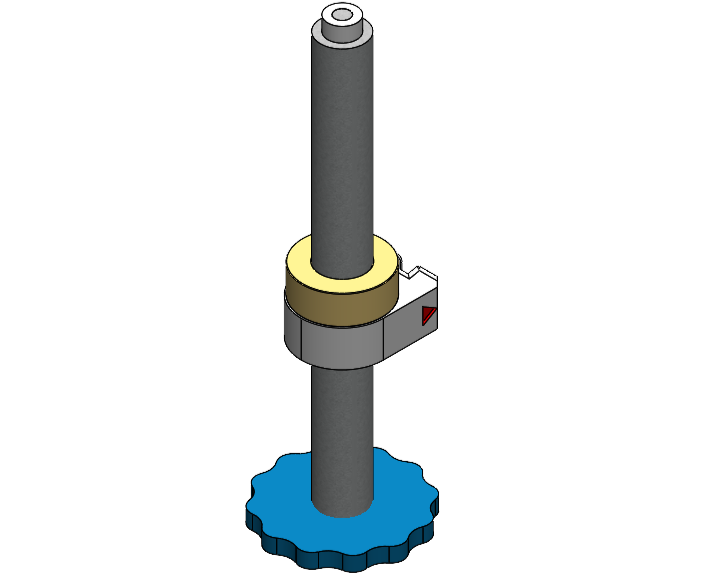

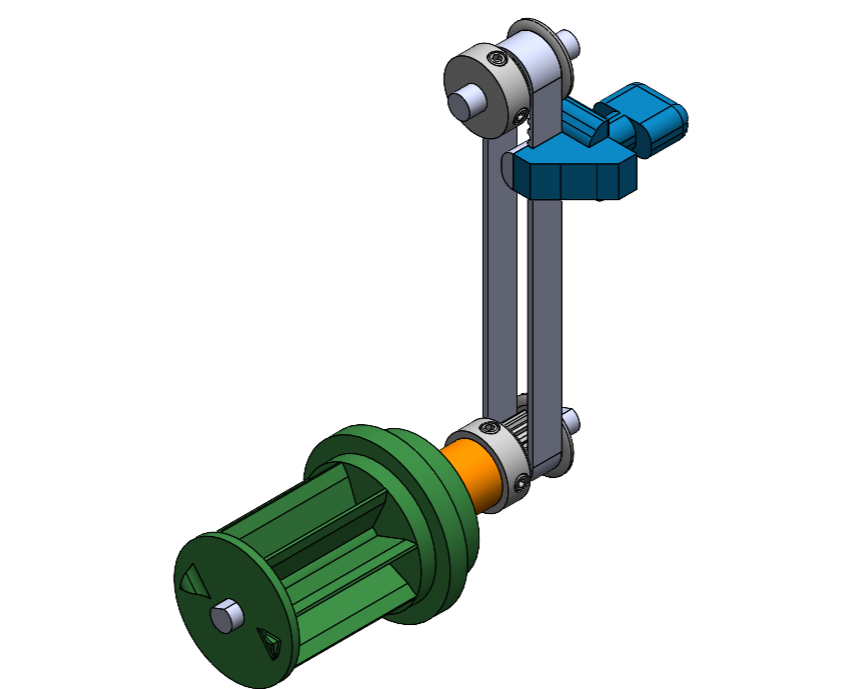

Our team produced 3 prototypes using FDM printing to replicate the small parts required for this product. Our final prototype features a high capacity hopper that feeds into a rotating drum with ¼ teaspoon partitions. Unlike any competitor products, our prototype allows the user to adjust a dial to set the measurement size and a linear belt and pulley drive to mimic the motion of dumping spices into a bowl.

Our next steps include optimizing our design to minimize jamming and more rigorously test our product. While we designed our product with manufacturing processes in mind, we recognize that there is potential for improving ease of assembly.

To learn more about our prototyping process, read our final report.

Final Prototype Right Side View

Final Prototype Left Side View

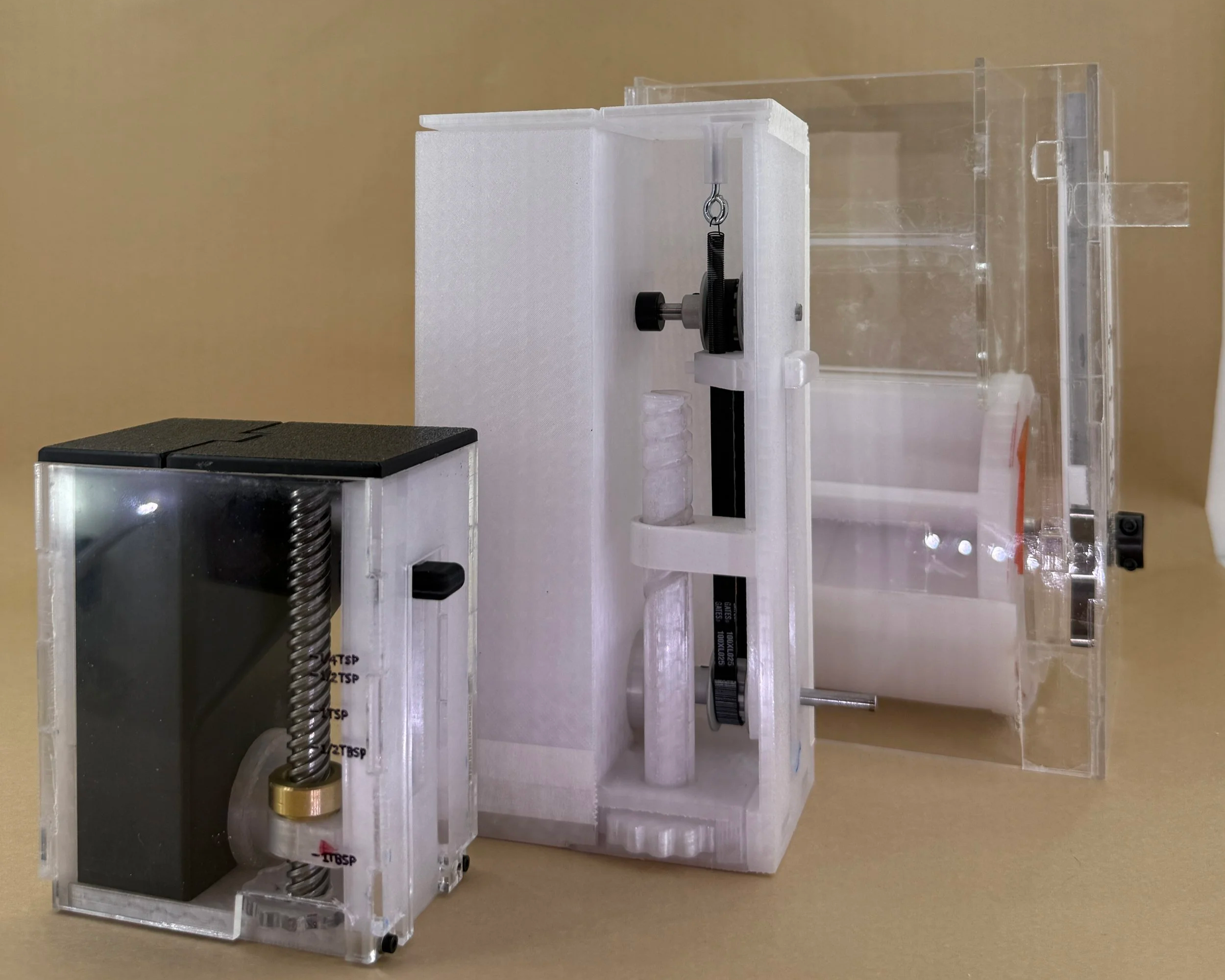

All Three Prototypes Front View

All Three Prototypes Right Side View

Final CAD Assembly Isometric Right View

Final CAD Assembly Isometric Left View

Final CAD Lead Screw Sub Assembly

Final CAD Shaft and Drum Sub Assembly